-

Empaquetadora de las bolsas

-

Empaquetadora del gránulo

-

empaquetadora líquida

-

empaquetadora del polvo

-

Mini Doypack Packaging Machine

-

Empaquetadora de la bolsita de té

-

empaquetadora del café

-

empaquetadora vertical

-

Empaquetadora del flujo

-

Levántese la empaquetadora de la bolsa

-

Máquina de empaquetamiento al vacío rotatoria

-

Máquina de rellenar

-

Empaquetadora horizontal de Doypack

-

Bolso preparado de antemano

-

Accesorios de la empaquetadora

-

máquinas de llenado y tapado

Máquina empacadora de ocho estaciones con alimentación por bolsa para gránulos de lentejas blancas

| Lugar de origen | Guangdong, China |

|---|---|

| Nombre de la marca | ZCHONE PACK |

| Certificación | ISO,CE |

| Número de modelo | ZC-8200 |

| Cantidad de orden mínima | 1 conjunto |

| Precio | $18000 |

| Detalles de empaquetado | Embalaje de estuches de madera de exportación estándar |

| Tiempo de entrega | 15 |

| Condiciones de pago | L/C, D/A, D/P, T/T, Western Union, Moneygram |

| Capacidad de la fuente | 1/sets/15day |

Éntreme en contacto con gratis las muestras y los vales.

WhatsApp:0086 18588475571

Wechat: 0086 18588475571

skype: sales10@aixton.com

Si usted tiene alguna preocupación, proporcionamos ayuda en línea de 24 horas.

x| Tipo | Máquina de envasado automático | Nombre del producto | Máquina de embalaje de múltiples estaciones de granules de alimentos |

|---|---|---|---|

| Dimensión (L*W*H) | L1900*W1400*H1450 | Peso (kg) | 1300 |

| Voltaje | 110V 220V 380V 50Hz/60Hz | Capacidad de producción | 20bag/min, 50bag/min, 30bag/min |

| Packing Machine Type | |

|---|---|

| Granule Packing Machine | |

| Liquid Packing Machine | |

| Powder Packing Machine | |

| Stand-Up Pouch Packing Machine | |

| Vertical Packing Machine | |

| Horizontal Packing Machine | |

| Tea Bag Machine | |

| Coffee Bean Packing Machine | |

| Horizontal Packing Machine |

Máquina envasadora de ocho estaciones alimentada por bolsas para gránulos de lentejas blancas

La máquina envasadora de ocho estaciones alimentada por bolsas para lentejas blancas es una máquina envasadora automática alimentada por bolsas diseñada específicamente para envasar lentejas blancas. Cuenta con ocho estaciones de trabajo (estaciones) para la operación de una línea de producción totalmente automatizada.

1. Análisis del concepto central

Lentejas blancas: El producto que se envasa. Se trata de un producto agrícola granular con las siguientes características:

Apariencia: Granular, de tamaño relativamente uniforme y con buena fluidez.

Requisitos: El proceso de envasado debe evitar el aplastamiento y la medición precisa.

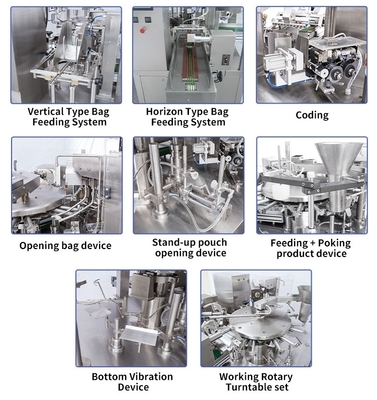

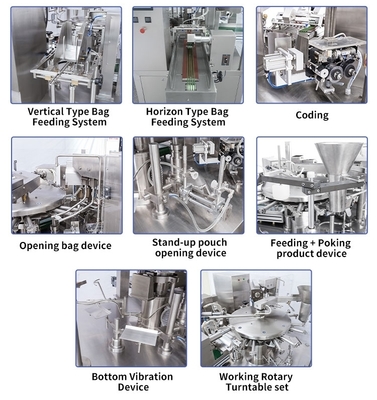

Máquina envasadora alimentada por bolsas: Un tipo de máquina envasadora.

2. Principio de funcionamiento:A diferencia de las máquinas envasadoras alimentadas por bolsas comunes (que comienzan con rollos de película, llenan y sellan), las máquinas envasadoras alimentadas por bolsas utilizan bolsas prefabricadas. La máquina completa automáticamente todo el proceso, incluyendo la extracción de la bolsa, la apertura de la bolsa, la medición y el llenado, la ventilación (opcional), el sellado y la descarga.

Ventajas:

Varios estilos de envasado: Se puede utilizar una variedad de hermosas bolsas prefabricadas de pie, bolsas autosoportadas, bolsas con cremallera y bolsas de mano, lo que mejora la calidad de sus productos.

Alta eficiencia: Particularmente adecuado para productos con variaciones de envasado limitadas, con velocidades estables.

Buena adaptabilidad del material: El llenado es suave y evita atascos para materiales granulares como las lentejas blancas.

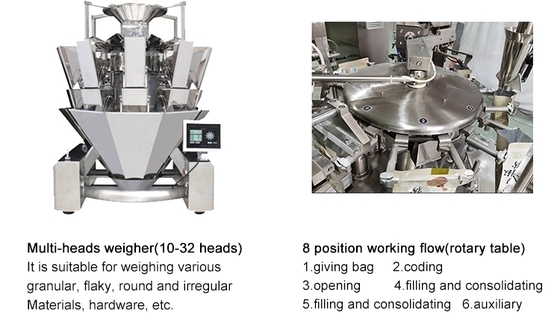

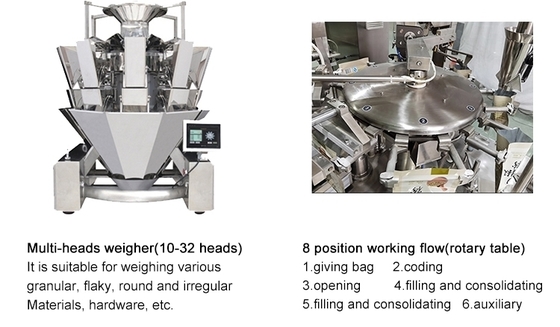

Ocho estaciones: El nivel de automatización y la complejidad funcional de la máquina.

Una estación se refiere a una estación de trabajo en la plataforma giratoria de la máquina envasadora, cada una responsable de un paso específico del envasado. Ocho estaciones significan que la máquina puede realizar ocho operaciones diferentes simultáneamente, lo que resulta en una eficiencia extremadamente alta.

3. Flujo de trabajo (Un sistema típico de ocho estaciones puede incluir los siguientes pasos):

Estación 1 (Carga de bolsas): Un robot o ventosa retira con precisión una bolsa prefabricada del almacén de bolsas.

Estación 2 (Apertura de bolsas): Una pinza agarra la abertura de la bolsa, y un soplador de aire o ventosa abre la abertura de la bolsa en preparación para el llenado.

Estación 3 (Llenado medido): Esta es la estación central. Utilizando una tolva gravimétrica (pesadora combinada multicabezal) o una taza medidora volumétrica, la cantidad precisa de lentejas blancas se vierte en la bolsa abierta. Esto es crucial para asegurar el peso preciso de cada bolsa.

Estación 4 (Vaciado vibratorio/Vaciado auxiliar): La vibración suave o un dispositivo de inserción de varilla aseguran que no quede material residual en la abertura de la bolsa y en la pared interior, lo que garantiza un sellado limpio.

Estación 5 (Ventilación): Para los productos que requieren ventilación, esta estación comprime la bolsa para expulsar el aire, haciendo que el envasado sea más ajustado, más estéticamente agradable y prolongando su vida útil (como puede ser necesario para las lentejas blancas).

Estación 6 (Sellado): La estación central. Una selladora térmica calienta y presuriza la abertura de la bolsa para completar el sellado. Este puede ser un sellado recto, un sellado trasero o un sellado en zigzag.

Estación 7 (Enfriamiento y conformado): El sellado térmico se enfría y se da forma para asegurar un sellado seguro y estéticamente agradable.

Estación 8 (Descarga y salida): Las bolsas terminadas envasadas se liberan en una cinta transportadora para la siguiente etapa (como el embalaje en cajas, la codificación y la inspección de metales).

Nota: El orden y las funciones específicas de las estaciones de trabajo se pueden personalizar en función del diseño del fabricante y las necesidades del cliente. Por ejemplo, se puede añadir una estación de inspección (por ejemplo, re-verificación del peso, detección de metales) o una estación de etiquetado.

4. Resumen del flujo de trabajo del equipo

Bolsa vacía → Carga automática de bolsas → Apertura de bolsas → Medición y llenado precisos con lentejas blancas → Recorte de la abertura de la bolsa → Eliminación de aire → Sellado a presión térmica → Enfriamiento y ajuste → Salida del producto terminado

Especificación de la máquina:

| Artículo | ZC-X8200 | ZC-X8250 | ZC-X8300 |

| Envasadovelocidad | MÁX. 60 bolsas/min, dependiendo de la calidad de la película de envasado, los materiales de envasado, el peso del envasado, etc. | ||

| Tamaño de la bolsa | (L)100-300mm (W)70- 200mm | (L)100-350mm (W)130- 250mm | (L)150-450mm (W)200-300mm |

| Tipo de bolsa | Bolsas prefabricadas, bolsa de pie, bolsa sellada por cuatro lados, bolsa sellada por tres lados bolsa, bolsa de forma especial | ||

| Rango de pesaje | 10g-1kg | 10g-2kg | 10g-3kg |

|

Medición precisión |

*≤±0.5~1%, dependiendo del equipo de medición y los materiales. | ||

| Ancho máximo de la bolsa | 200mm | 250mm |

300mm |

| Consumo de gas | 0.8Mpa 0.3m3/min (Suministro por el usuario) | ||

| Total Potencia/Voltaje | 2.5KW 380V 50/60Hz | 2.5KW 380V 50/60Hz | 3.7KW 380V 50/60Hz |

| Compresor de aire | No menos de 1CBM | ||

| Dimensión | L1900*W1400*H1450 | L1900*W1400*H1450 | L2000*W1500*H1550 |

| Peso de la máquina | 1300kg | 1400kg | 1500kg |

| Flujo de trabajo | Dar bolsa→Codificación→Abrir bolsa (o abrir bolsa con cremallera)→Llenado→ Auxiliar→Escape→Sellado térmico→Formación y salida de productos. | ||

| Ámbito de aplicación | Tipo granular: glutamato monosódico cristalino, medicamento granular, cápsula, semillas, productos químicos, azúcar, esencia de pollo, semillas de melón, nueces, pesticidas, fertilizantes, etc. | ||

(¡Podemos proporcionarle servicios personalizados exclusivos según sus necesidades!)

![]()

![]()

![]()

![]()